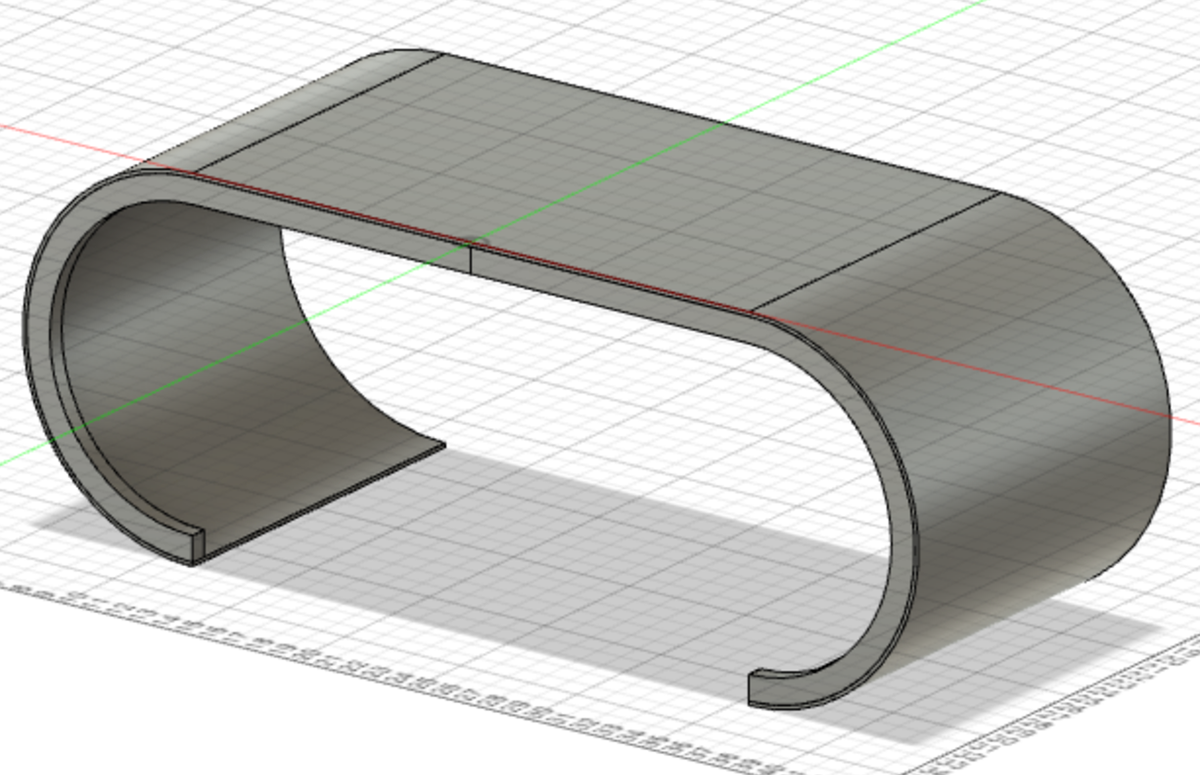

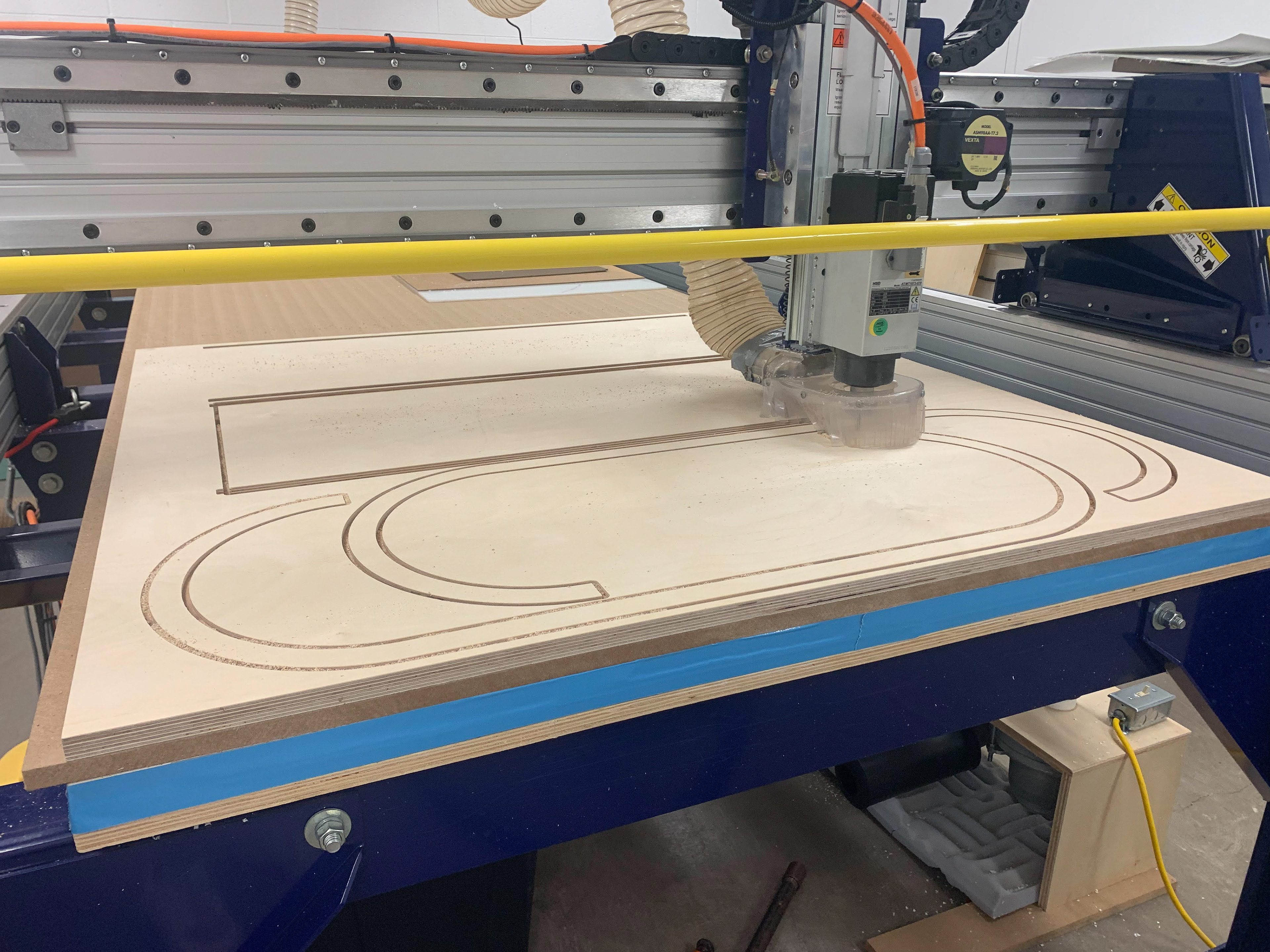

In this project, I used digital design and fabrication techniques within the context of contemporary art, design, and critical making. I used computer-aided-design/computer-aided-manufacturing (CAD/CAM) software, digital fabrication technologies, and the physical world to create a piece of furniture that is both modern and practical. The first step was to gather inspiration. My goal was to create something unique, functional, and beautiful. I created a number of sketches and brainstormed ideas for the project. I was really drawn to curves. But was challenged with the question of how to bend wood. I ultimately settled on a fully curved leg for the table using kerf bending. With the limited material we were given (4x4 feet), I needed to think outside the box to make this work. Once I figured out if my design was even going to work considering the material we were given, I designed a mock-up of my table. Using CAD application software Autodesk Fusion 360, I rendered my final design. Once my design was completed, I saved the file and brought it into Vectric Aspire where I programmed what cuts we wanted the CNC machine to make. Once programmed, we took it over to the machine and watched the magic happen. The machine made very rough cuts, so it was really up to us to perfect it. I can't even begin to tell you how much time was spent sanding. Assembling the table was my favorite part of the experience because I could finally see my vision come to life. I started by creating biscuits to attach the two larger pieces of wood together and to create one long eight-foot board. Once the glue dried I wrapped the eight-foot board around my curved frames to create the curvy silhouette. I then used glue to bind the parts and waited for it to dry. Then I scraped off the excess glue, sanded, and finished the table with polyurethane.